18.02.05 [BNK Partner] Customer Satisfaction Realized with the Best Quality

본문

Customer Satisfaction Realized with the Best Quality

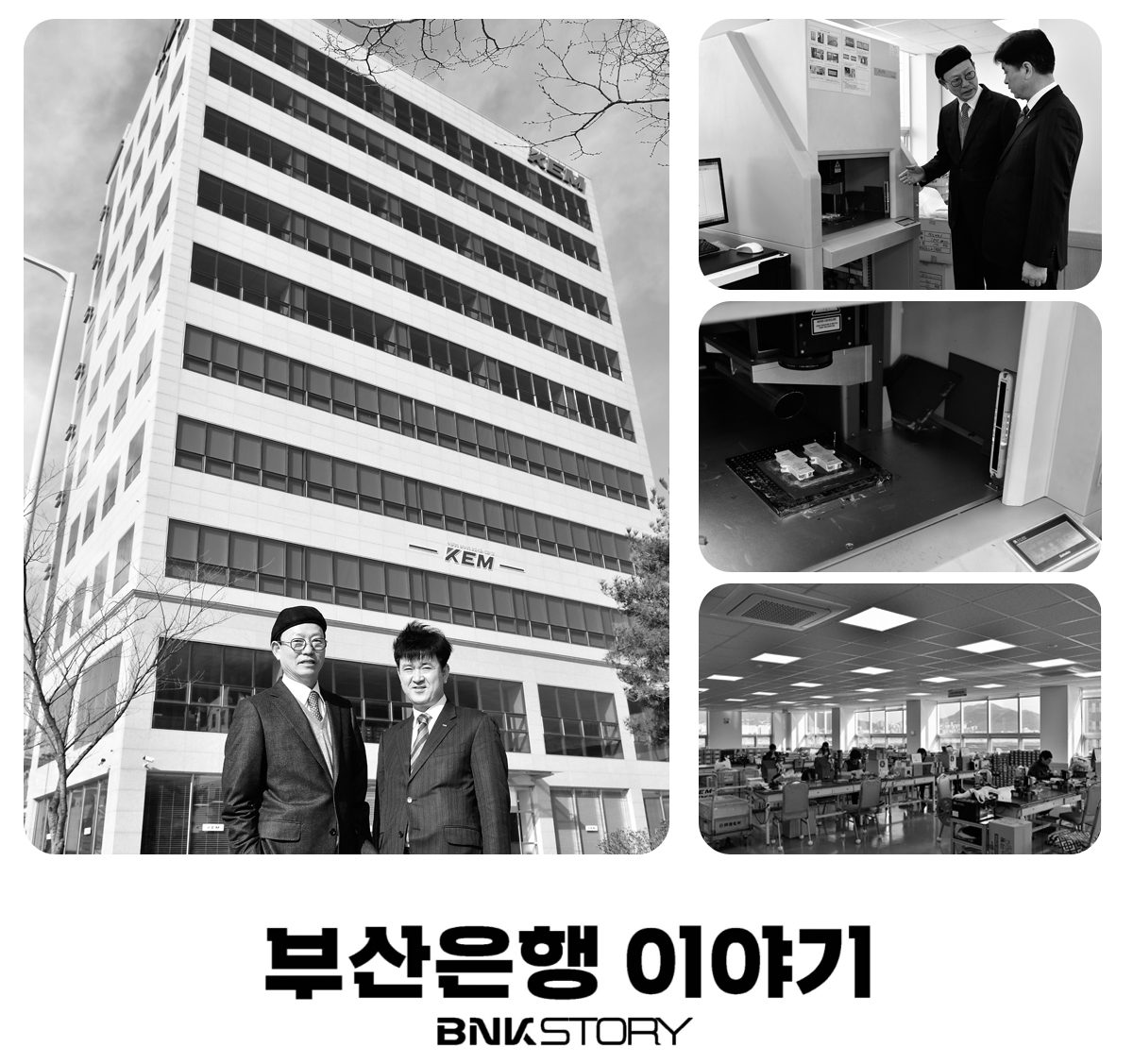

KEM Co., Ltd. Juong deuk Noh CEO

The merits that can be obtained by possessing the country's own technology are limitless. It can reduce royalties paid for advanced overseas technologies, and it can become a technology suzerain and export its technologies. However, in order for the technology to reach a certain level, a lot of blood and sweat is required. Roh Jeong-deok, CEO of KEM, has been leading the localization of machine tool parts in Korea by walking the path of localization of technology, which is not easy.

1988.07 Established Korea Electrical Equipment Industry Co., Ltd.

2002.08 OIL SKIMMER development and production

2004.10 Acquired Busan Bank Promising Small and Medium Business Certificate

2006.06 ISO 9001 Quality Management Certification

2007.03 Selected as a company specializing in parts and materials by the Ministry of Knowledge Economy

2008.07 Establishment of Korea Electronic Materials Co., Ltd.

2011.01 Changed company name to KEM Co., Ltd.

2014.12 Received the Excellent CEO Award on the 14th Machine Tool Man Day

2017.10 Received Presidential Commendation for Excellent Capital Goods Development

Break stereotypes about domestic products

KEM Co., Ltd. is a company that produces parts related to automation and machine tools. KEM Co., Ltd. CEO Noh Jeong-deok worked in Seoul and was dispatched to the company's Busan sales office, settling down in Busan and starting his own business. The reason why I decided to start the business was because I felt sorry for the reality of using expensive foreign products even in the field of materials and parts that could be localized with a little effort. In order to overcome the limitations of imported products that are not only expensive but also do not have proper follow-up management, research on alternative products was initiated.

“What was more difficult than product development was breaking people's stereotypes. It was difficult to deal with problems caused by hasty use of domestic products that had never been used, so they continued to settle for expensive foreign products. However, because we were confident that the product was sufficiently competitive in terms of both price and quality, we constantly tried to make deals, and changes slowly began to occur.”

At first, it started supplying for Hyundai's domestic market. Then, as the safety of the product was recognized, KEM's products gradually began to be used for export. One success breeds another success. Other companies, such as Daewoo and Doosan, also tried to use KEM's products. KEM returned the hearts of domestic industrial engineers who did not believe in their own technology.

It is not an exaggeration to say that there is no machine in Korea that does not use KEM's products. This is because KEM's main products are parts that go into machine tools (Mother Machine), that is, 'machines that make machines'. With the idea that it is the source of smooth operation of the Korean industry, the employees of KEM Co., Ltd. are putting their heart and soul into each and every product production process.

Production of demanding products for customer satisfaction

KEM Co., Ltd. produces various products such as Interface Cover, Spark Killer, and SPD (Surge Protector Device). Among them, the ‘Oil Skimmer’ boasts the highest quality. An oil skimmer is a device that filters the oil flowing into the cutting oil required for the product production process. It enables accurate product processing to reduce product defect rates and minimizes environmental pollution by preventing contamination of cutting oil. It used to be an option, but as interest in eco-friendliness increases, it is now mandatory to install it on all machines. Naturally, as the demand for oil skimmers rose, KEM's products became more popular with customers.

“The most important thing for companies is customer satisfaction. However, in the end, it is quality that realizes customer satisfaction. You can use a cheap product even if the quality drops once, but eventually you won't use it. Because our customers know that good parts are necessary to make good products. So, we go into production with the determination that our products will not break down until the machine is scrapped.”

With reasoned insistence on quality and steady localization of technology, KEM Co., Ltd. was selected as a promising small and medium-sized company by Busan Bank in 2004. CEO Noh Jeong-deok, who has been dealing with Busan Bank ever since the Sasangseo Branch was established, is of course in the position that he should use Busan Bank because he is a Busan citizen.

“Busan Bank is strong. Local residents joined the company and formed the company, and because it works for local customers, it has potential that commercial banks cannot have. So, as a Busan company, I can trust and entrust the company's assets. I have to make a deposit at Busan Bank so that the bank can use that as a basis to support other companies in need, and the region, the bank, and companies can all coexist.”

‘Deep-rooted trees do not shake’ is the philosophy of CEO Jeong-Duk Noh. Just as Busan Bank is advancing to become a 100-year bank based on solidarity unique to regional banks, KEM Co., Ltd. is also determined to become a 100-year company by taking root more deeply with Busan Bank.

Until the day we are proud of our world-class technology

We regularly attend domestic and foreign machinery related exhibitions such as SIMTOS (International Manufacturing Technology Show). KEM Co., Ltd. aims to open export markets by promoting products to foreign buyers at KOFAS, Korea International Machinery Fair (KIMEX), and SIMTOS (Seoul). Although it has quality competitiveness, CEO Noh Jeong-deok never settles for the present.

“The challenge is to export all of our products to the Japanese market. Most Japanese companies are long-lived companies with a long history, so they are proud enough to insist on only their own products, even if they are a bit expensive. Since we are so picky about overseas products, we can be proud of having world-class technology only when they are recognized by them.”

Along with the plan to develop overseas markets and increase the proportion of exports to 50%, the company-affiliated research institute is accelerating the development of new products. Efforts to further refine existing products will also be made continuously.

“When you evaluate yourself, there is a 2% lacking part. You have to reinforce it first. Along with the development of new products, there is a need to upgrade existing products to the next level. In order to develop further in the future, you have to go once. I don't think we should be satisfied first because our customers have no complaints.”

CEO Roh Jeong-deok will also accept the 2017 Presidential Commendation for Excellent Capital Goods Development as a stick to do better in the future rather than praise for what has been done so far. KEM Co., Ltd., which makes parts for machines that are the basis of machines, will continue to do its best as a leading force in Korea's industry.