17.10.24 2017 Received Presidential Commendation for Excellent Capital Goods De…

본문

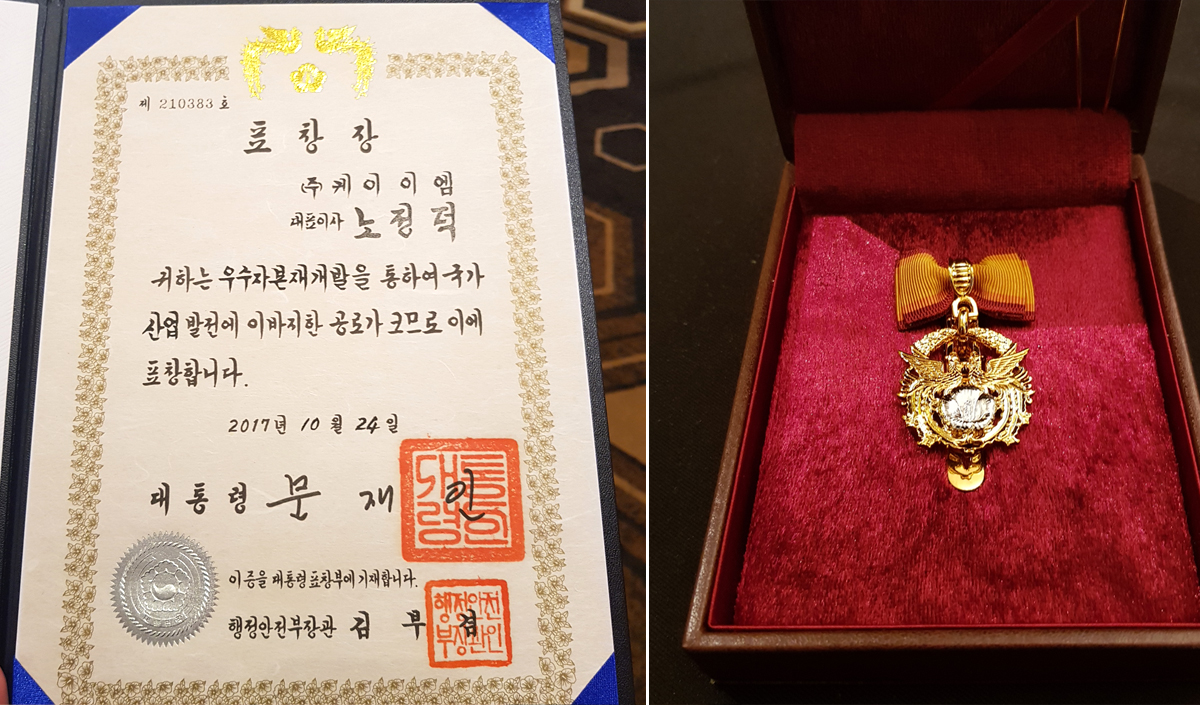

2017 Received Presidential Commendation for Excellent Capital Goods Development

On the 24th, at the '2017 Capital Goods Industry Development Contributor Award Ceremony' held at the Grand Ballroom on the 3rd floor of KINTEX Exhibition Center 1, hosted by the Ministry of Trade, Industry and Energy, KEM Co., Ltd. (CEO Jeong-deok Noh) was recognized for its contribution to the development of the national industry and received a Presidential Commendation. Awarded.

The event was attended by about 300 heads of related institutions and machinery industry people, and 39 people of merit who contributed to the development of the domestic capital goods industry through localization and technology development were awarded medals, medals, presidential citations, and prime minister and ministerial citations. The award for contribution to the development of the capital goods industry has been held since 1984 to boost the morale of employees in the machinery industry who have devoted themselves to securing the world's best technology in the core capital goods field, which is highly dependent on imports.

▲ CEO Noh Jung-deuk of KEM Co., Ltd. received the Presidential Commendation

▲ At the event, KEM Co., Ltd. CEO Noh Jung-deuk and 38 others were rewarded for their contributions.

KEM Co., Ltd.

It is a venture company that succeeded in localizing parts related to automation and machine tools that had been dependent on imports in the late 1980s when the domestic parts industry was very weak.

As a company that has steadily led the localization of parts for over 20 years, it has developed a variety of product groups that can be used appropriately according to the type of machine and structure of the site every year, broadening the range of choices for customers.

One of the representative items, the oil skimmer, effectively separates the non-aqueous oil floating on the surface of the cutting oil tank of the machine tool. In particular, as interest in clean sites has recently increased across all industrial fields, the demand for oil skimmers to be installed in various production facilities including machine tools is increasing. In this situation, KEM Co., Ltd. CEO Noh Jeong-deok developed a tube-type oil skimmer that is easy to install and separate in 2016, drew attention from customers, and started mass production. This product is effective in continuously removing surface layer oil by using a special lipophilic tube with a diameter of 6mm. In addition, it is designed as an integral tube type, so it has excellent durability, and has the advantage of convenient management due to its movable structure. Currently, it is widely used in various production sites such as processing product cleaning tanks, heat treatment, painting factory grinding machines, machining centers, and CNC lathes, and is widely publicizing KEM's advanced technology.